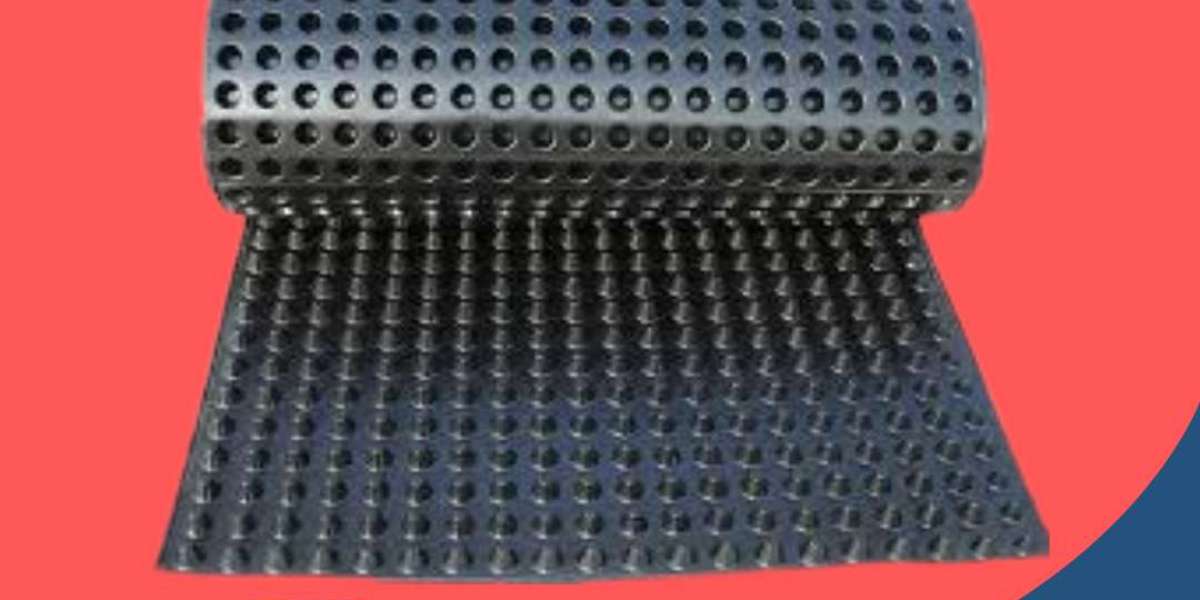

In today’s world, where sustainable development and long-term durability are of utmost importance, HDPE T-Rib liner sheets have emerged as an exceptional solution for various engineering and construction projects. These high-density polyethylene sheets are designed to provide unparalleled strength, chemical resistance, and long-lasting performance. Their versatility has made them a preferred choice for lining applications in industries such as wastewater management, tunnels, canals, and more. Below, we delve deeper into the benefits, applications, and market dynamics of HDPE T-Rib liner sheets while highlighting essential information on lining sheet manufacturers, HDPE T-Rib sheet suppliers, and the HDPE T-Rib sheet price landscape.

Exceptional Durability of HDPE T-Rib Liner Sheets

One of the standout features of HDPE T-Rib liner sheets is their exceptional durability. These sheets are engineered to withstand harsh environmental conditions, including exposure to UV rays, chemicals, and mechanical stress. Unlike traditional materials, HDPE T-Rib liner sheets offer a significantly longer lifespan, reducing the need for frequent replacements. This makes them an ideal choice for sustainable engineering projects where longevity and reliability are critical.

For project managers and engineers seeking dependable solutions, lining sheet manufacturers play a vital role in ensuring product quality and consistency. By sourcing HDPE T-Rib liner sheets from reputable suppliers, one can ensure optimal performance and value for money.

Superior Chemical and Abrasion Resistance

HDPE T-Rib liner sheets are known for their excellent resistance to a wide range of chemicals and abrasive substances. This property makes them particularly suitable for applications in wastewater treatment plants, chemical storage facilities, and mining operations. The ribbed structure enhances the sheet’s bonding capability with concrete and other substrates, ensuring a secure and long-lasting lining system.

Leading HDPE T-Rib sheet suppliers like Mahira Polyglobal LLP emphasize this resistance in their products to cater to industries with demanding operational conditions. The availability of customizable options further enhances the applicability of these sheets, making them a top choice for various industrial applications.

Eco-Friendly Construction Solutions

Sustainability is a key concern in modern construction, and HDPE T-Rib liner sheets contribute significantly to eco-friendly practices. These sheets are recyclable, reducing the environmental impact of construction waste. Additionally, their longevity minimizes the resources required for replacements and repairs, making them a sustainable choice for large-scale infrastructure projects.

Lining sheet manufacturers have increasingly focused on producing environmentally responsible HDPE T-Rib liner sheets. By incorporating advanced manufacturing techniques and high-quality raw materials, they ensure the sheets meet both performance and sustainability criteria.

Wide Range of Applications

HDPE T-Rib liner sheets are highly versatile and find applications across numerous sectors. Some of the most common uses include:

Tunnel Linings: The sheets provide a reliable waterproofing solution, protecting tunnels from water ingress and structural degradation.

Canal Linings: Their resistance to abrasion and chemical exposure ensures the long-term performance of canals.

Storage Tanks: HDPE T-Rib liner sheets prevent chemical corrosion in storage tanks, safeguarding their structural integrity.

Sewage Treatment Plants: The sheets offer a durable lining solution, minimizing leaks and contamination risks.

The adaptability of HDPE T-Rib liner sheets underscores the importance of partnering with established HDPE T-Rib sheet suppliers to ensure the right product is used for each application.

Competitive HDPE T-Rib Sheet Price

When considering the cost of HDPE T-Rib liner sheets, it’s important to balance initial expenses with long-term benefits. While the upfront HDPE T-Rib sheet price may seem higher compared to traditional materials, the reduced maintenance and replacement costs offer significant savings over time. Additionally, the enhanced durability and performance justify the investment, particularly for projects requiring high reliability.

HDPE T-Rib sheet suppliers often offer a range of options to suit various budgets and requirements. By consulting with these suppliers, project stakeholders can make informed decisions that align with their financial and operational goals.

Importance of Reliable Lining Sheet Manufacturers

The quality of HDPE T-Rib liner sheets largely depends on the expertise and capabilities of the manufacturers. Reputable lining sheet manufacturers invest in advanced production technologies and stringent quality control processes to deliver products that meet international standards. This ensures the sheets perform as expected, even in the most demanding conditions.

Collaboration with trusted manufacturers also provides access to technical support and customization options, enabling engineers to design tailored solutions for specific project needs.

Easy Installation and Maintenance

Another significant advantage of HDPE T-Rib liner sheets is their ease of installation. The lightweight nature of these sheets simplifies handling and reduces installation time, leading to lower labor costs. Furthermore, their compatibility with a variety of installation methods enhances their utility across different projects.

Maintenance is equally straightforward, as the sheets’ resistance to wear and tear minimizes the need for extensive repairs. For industries looking to optimize operational efficiency, partnering with reliable HDPE T-Rib sheet suppliers ensures access to high-quality products that require minimal upkeep.

Innovations in HDPE T-Rib Liner Sheets

Recent advancements in material science and manufacturing techniques have further elevated the performance of HDPE T-Rib liner sheets. Innovations include improved rib designs for better bonding, enhanced UV resistance, and the incorporation of additives to extend lifespan. These developments reflect the commitment of lining sheet manufacturers to meet evolving industry demands and provide cutting-edge solutions.

Global Market Trends and Demand

The global demand for HDPE T-Rib liner sheets is on the rise, driven by the increasing emphasis on sustainable infrastructure development. Industries such as construction, mining, and water management are key contributors to this growth. The competitive landscape among HDPE T-Rib sheet suppliers has led to a broader range of products and competitive pricing, benefiting end-users.

Choosing the Right Supplier

Selecting the right HDPE T-Rib sheet suppliers is crucial for ensuring the success of any project. Factors to consider include product quality, customization options, delivery timelines, and technical support. By conducting thorough research and comparing offerings, stakeholders can identify suppliers that align with their project requirements and budget.

Future Prospects of HDPE T-Rib Liner Sheets

As sustainability continues to gain prominence in engineering and construction, the future of HDPE T-Rib liner sheets looks promising. Ongoing innovations and an expanding range of applications are likely to drive further adoption of these high-performance materials. Collaborations between lining sheet manufacturers and industry leaders will play a key role in shaping this future.

Conclusion

HDPE T-Rib liner sheets represent a significant advancement in sustainable engineering materials. Their exceptional durability, chemical resistance, and eco-friendly properties make them an invaluable asset for modern infrastructure projects. By partnering with reliable Lining sheet manufacturers and HDPE T-Rib sheet suppliers, stakeholders can ensure access to high-quality products that deliver long-term value. While the initial HDPE T-Rib sheet price may be higher, the cost savings and performance benefits over time make them a wise investment for any project focused on sustainability and reliability.

Frequently Asked Questions (FAQS)

1. What are HDPE T-Rib Liners?

HDPE T-Rib Liners are sheets made from High-Density Polyethylene (HDPE) with a unique T-shaped rib pattern on one side. These liners are used to protect and reinforce concrete structures, primarily in sewage and wastewater systems.

2. How do HDPE T-Rib Liners work?

The T-shaped ribs on the liner sheet interlock with the concrete during construction, creating a strong bond. This prevents the concrete from directly contacting corrosive elements like wastewater, extending the life of the structure.

3. What are the benefits of using HDPE T-Rib Liners?

- Corrosion Resistance: Protects concrete from chemical attack and abrasion, increasing its lifespan.

- Improved Flow: The smooth inner surface of the liner reduces friction, improving the flow of wastewater.

- Reduced Infiltration: Prevents groundwater infiltration into the sewer system.

- Cost-Effective: Can be a more economical solution compared to replacing or repairing damaged concrete structures.

- Easy Installation: Relatively easy to install during new construction or as a rehabilitation measure.